FRAMES

- Composite

Fiber Reinforced thermoplAstics Manufacturing for stiffEned, complex, double curved Structures is a collaborative Research & Development project under the European research and innovation programme Clean Sky 2 Joint Undertaking.

The next generation of large airliner fuselages will certainly be based on the advantages of thermoplastic composites. Durability, recyclability and faster production cycles will meet the future challenges of the aerospace industry. This type of material is being used more and more in the aerospace industry because it helps to reduce aircraft weight and therefore fuel consumption, but there are still many problems to be solved before this becomes a reality: high processing temperatures, raw material costs, complex temperature control tools and scalable cross-sections.

To explore solutions, ESTIA - Compositadour has formed a European consortium with Heraeus Noblelight Ltd, Xelis (Germany) and Cero (France) to support the Clean Sky 2 initiativewith a two-and-a-half year applied research project, FRAMES.

The project partners therefore decided to develop solutions for manufacturing high-performance thermoplastic composites for the Advanced Rear End demonstrator produced by the DLR (Deutsches Zentrum für Luft- und Raumfahrt).

- Predictive heating model using Humm3 technology for skin draping.

- Thermoplastic frames and stiffeners.

- Stand-alone tooling solution for one-shot co-consolidation of the skin and stiffener assembly.

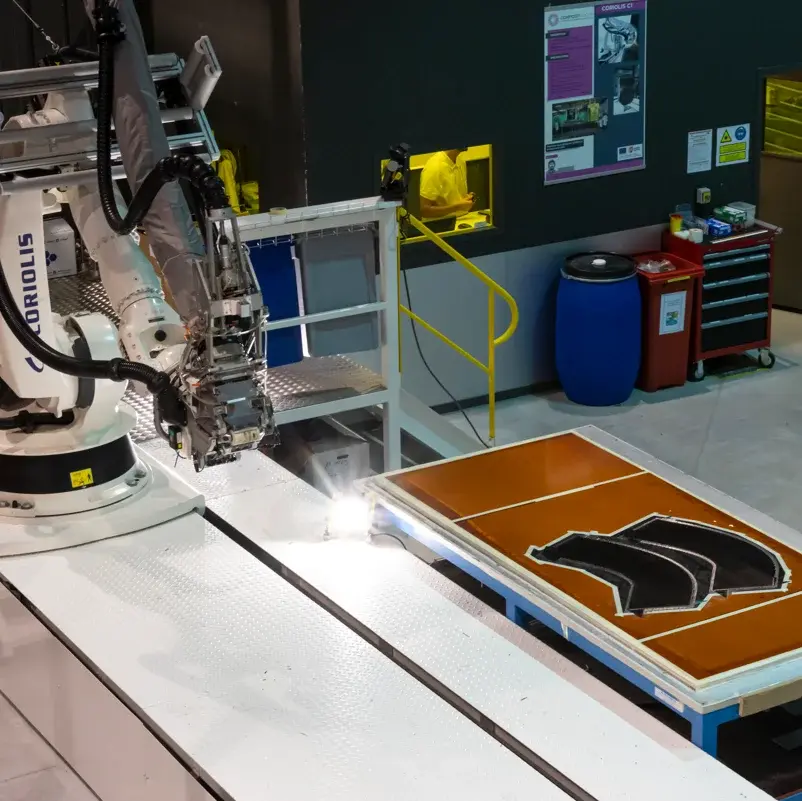

Compositadour draped the Z-shaped fuselage frame preforms using an automated fibre placement process. These preforms were then formed under press using a hot stamping process by our teams.